HOME

News

Exhibitions

【CHINAPLAS 2023 - World Plastics and Rubber Trade Fair】Plastics Processing Industry 4.0: Integration of Digital Factory & Automation Cloud Platform

Exhibitions

2023-03-30

【CHINAPLAS 2023 - World Plastics and Rubber Trade Fair】Plastics Processing Industry 4.0: Integration of Digital Factory & Automation Cloud Platform

Technology Trends Report

Envisioning a Techmation digital Vision

2023 CHINAPLAS will be held in Shenzhen World Exhibition & Convention Center in China. Techmation has been engaging in the automation field of the rubber and plastics industry for nearly 40 years, enabling it to provide intelligent manufacturing solutions of industrial control, drivers, communication bus, motion modules, control modules, online manufacturing management, IoT and etc. to achieve a giant leap on the way marching towards "Digital Factory". We have been playing a leading role in developing the rubber and plastics industry towards intelligence, digitization, informatization and low-carbon emissions. In this trade fair, we will demonstrate multiple sets of our products and introduce the latest industrial solutions.

__

Exhibition Information

Date: April 17-20, 2023

Location:Shenzhen World Exhibition&Convention Center

(No.1 Zhancheng Road, Fuhai Street, Bao'an District, Shenzhen City, Guangdong Province, China.)

Booth: Hall . 07 F21

__

Techmation|Attractions at 2023 CHINAPLAS

Techmation|Attractions at 2023 CHINAPLAS

A. Digital Factory Service

Our digital factory service platform is to facilitate the digital transformation of enterprises, providing full digital service in multiple application scenarios of IoT and supporting large-scale innovation. The platform has been contributing to the digital transformation of the industry, leading the high-quality development of the industry and building a new ecosystem of the industry.

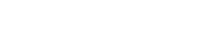

TM PLAS CLOUD

Our TM PLAS CLOUD, integrated with the injection molding control system, providing intelligent factory solutions including real-time equipment monitoring, equipment management, process management, production management, quality management and etc. through edge computing, big data analysis and other means, so as to realize the digitalization, informatization, intelligence and low carbon emission in the production process.

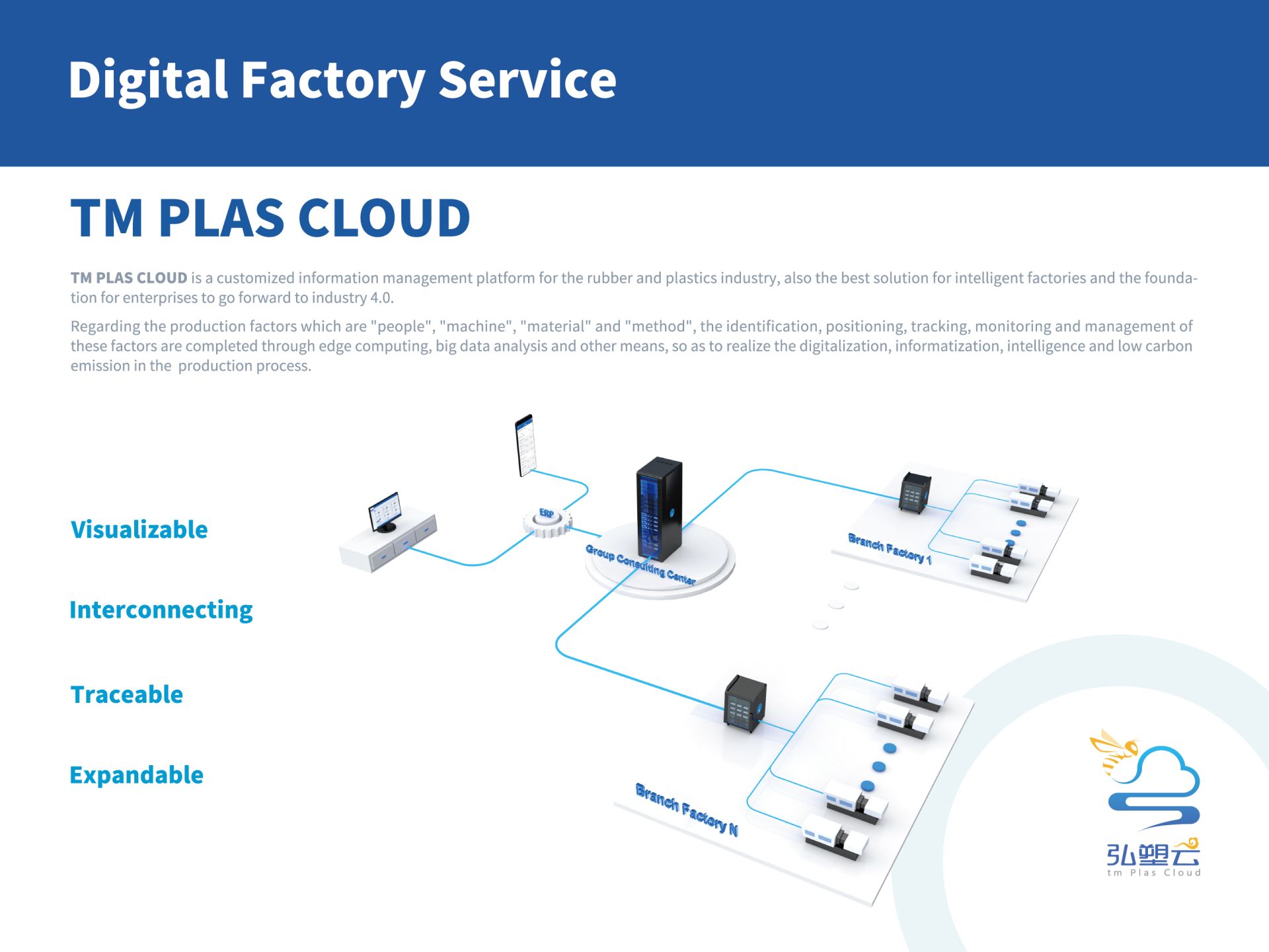

“tmIoT”- IoT Cloud Platform

The IoT cloud platform is built based on our independently researched and developed industrial operating system “NectarOS”, with private clouds.

tmIoT® IoT Cloud Platform, with standard components and programming characteristics of no-code, modular design and low threshold, making IoT applied just through cloud tools with simple configuration which is like building blocks and offering one-stop service which integrates the control with the management.

B. Full Digital Control System Solution -

The iTECH system adopts SA-BUS control which is independently researched and developed by Techmation, with full digital communication, simplified wiring, better real-time performance, enhanced stability and improved expansion capabilities, bringing more possibilities to injection molding. The system carries diverse intelligent control, making plastics machines more efficient, energy-saving, and precise. The system provides intelligent control of mold opening and closing as well as self-learning positioning control, with easy commissioning, repetition accuracy≤± 0.2 mm and positioning accuracy≤1 mm. The system provides intelligent multi-stage control of oil pressure, optimizing the flow rate of each action based on oil cylinders, reducing the wasted flow, and lowering the impact on the oil circuit. Meanwhile, with dynamic curve display of injection, it is easy to control the status and process of the injection. Online monitoring allows for direct debugging and monitoring of the servo system on the HMI, which is convenient and fast. With intelligent reminders of system maintenance, customers are reminded to inspect or maintain a certain component according to actual needs.

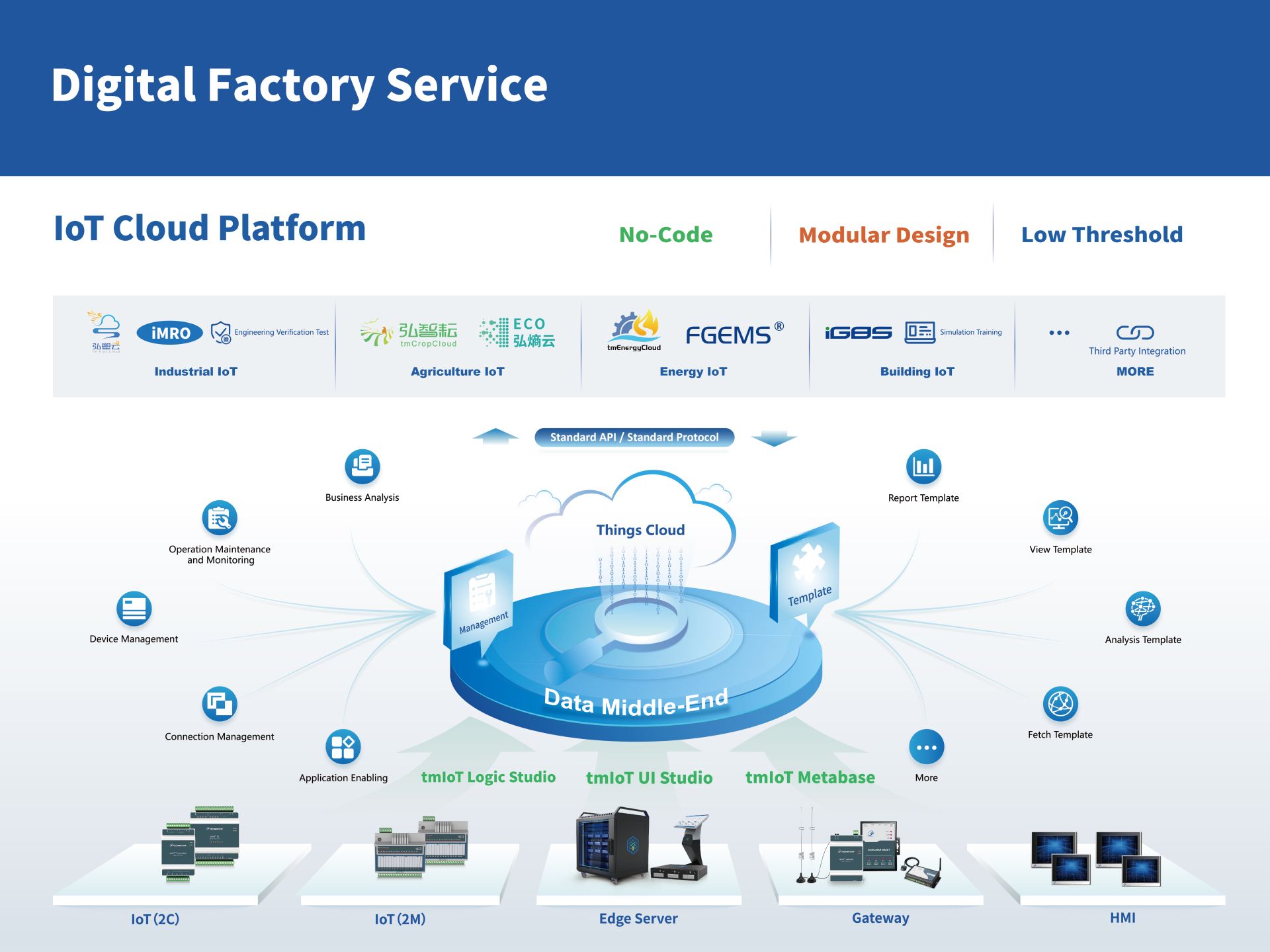

C. Open All Digital Solution - iREX Series

The solution is a processor hardware platform based on Cortex-A53 and a new generation of electronic control system that complies with PLCopen specifications. Carrying high-speed SA-BUS based on Ethernet and built-in motion control modules “PLC SoftMotion”independently researched and developed by Techmation, it is suitable for precise and high-speed industrial control of sophisticated equipment. Through expansion, it is also suitable for applications such as image recognition, audio and video processing, the Internet of Vehicles, the Internet of Things, and smart cities.

D. Full Electric/ Hybrid Control System Solution-SANDAL Series

The solution adopts the SA Communication System independently researched and developed by us, which integrates perfectly with our high-end control system of plastics machinery (SANDAL II), advanced manipulator control system (THUJA) and other auxiliary equipment. It also carries our latest HIVE server and through the management software, customers are able to do equipment management, process management, real-time monitoring, process tracing and etc.. It is an integrated solution for digital factories.

The solution is highly cost-effective with easy implementation, good reliability and convenient management, contributing to the digitalization of plastics processing industry.

Contact person:Shen Yanan

Mail:assistant@techmation.com.cn/sales2@techmation.com.tw

Tel.:0574-86987281/86987282

Address:No. 88 Dagang Fifth Road, Beilun District, Ningbo City, Zhejiang Province, China.

Mail:assistant@techmation.com.cn/sales2@techmation.com.tw

Tel.:0574-86987281/86987282

Address:No. 88 Dagang Fifth Road, Beilun District, Ningbo City, Zhejiang Province, China.