Exhibitions

2024-03-15

INVITATION | Join Us at the ITES China Held in Shenzhen

Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition

INTRODUTION

Established in 2000, ITES is among the most sizable industrial exhibitions in China. It has been honored with the esteemed designation of "Shenzhen Brand Exhibition" for a consecutive thirteen years. The ITES 2024, with the theme Navigating Changes and Striving for Excellence, will be held at the Shenzhen World Exhibition & Convention Center (Baoan Venue) from March 28th to March 31st. Techmation, along with its subsidiary Spectrum, will be participating in this event, and we warmly welcome you to participate in our discussions and investigate emerging market trends.

__

Booth Overview

Booth Overview

March 28th to March 31st

Techmation ● Spectrum × ITES

Shenzhen World Exhibition & Convention Center (Baoan Venue)

We anticipate your presence at Booth 4-Q36.

Techmation ● Spectrum × ITES

Shenzhen World Exhibition & Convention Center (Baoan Venue)

We anticipate your presence at Booth 4-Q36.

__

Highlight Preview

Highlight Preview

1. Bending Machine

All-Electric Solution

Lead screw transmissions have superior positioning precision and repeatability; demand-based operation reduces energy consumption; action response is accelerated with smoother transitioning; and there is no oil contamination.

Electro-Hydraulic Servo Solution

Speed and overflow pressure adjustments that reduce oil temperature and noise significantly; Mosfit valves with a quicker response time than the relay; connection to the MES system to analyze production-related energy consumption.

High-Speed Pump Controlled Solution

This solution combines the benefits of servo electric and hydraulic valve control systems for bending machines, offering a combination of rapid speed, accurate positioning, and affordability. Energy efficiency, high productivity, and cost-effectiveness are all contained within it. Regarding motion control, it has the ability to regulate the speed of rapid descent, reduce action transition durations, and enhance jogging capabilities.

2. Servo Unit

Integrated Electro-hydraulic Servo Unit

It is an integrated system that combines a servo driver and motor. It includes a permanent magnet synchronous motor and has analog and digital communication interfaces. This design results in a more compact structure, simpler operation, and superior performance at low oil temperatures and noise. It works well with a wide range of machines, such as hydraulic power units, hydraulic machines, oil sealers, vacuum vulcanizers, bending machines, and vertical injection molding machines.

3. Hydraulic Press

Hydraulic Press Control System Solution

Instead of using a conventional PLC and asynchronous motor, this solution uses our specialized hydraulic press control system coupled with our high-response electro-hydraulic servo system. The system's in-built TMPLC SoftMotion motion control algorithm allows for exact regulation of pressing displacement and molding pressure. Applying our specialized hydraulic press control system can significantly enhance hydraulic presses' accuracy, stability, intelligence, production efficiency, energy savings, and consumption reduction—all while increasing their market competitiveness—thanks to the system's powerful software capabilities, extensive application experience, and superior control performance.

- 1% Full-Range Pressure Accuracy

- ±0.01mm Position Repeatability

- 1ms System Control Cycle

4. Rolling Machine

Rolling Industry Solution

We have created an industrial control system specifically designed for rolling machines. It includes a large capacitive touch screen, which enhances its visual appeal and improves the interaction between humans and machines. Its built-in automatic circle rolling, cone rolling, and square-to-round rolling templates make programming simpler, and it allows users to create their own templates. It offers more flexible programming to shape special-rolled products. It permits connection and collaboration with feeding platforms and automation lines, allowing for smooth integration into production processes. Its networking function enables online diagnostics and remote assistance, resulting in convenient technical support and troubleshooting.

5. Bending Forming

Bending and Forming Industry Solutions

Repeated Bending: The parameters of repeated bending can be added to the original bending step parameters;

Graphic Transformation: Easily and quickly edit various irregular-shaped images;

Graphic Programming: The pre-input function in the table (gray 0 in the last row of the step) enables rapid input;

Tools: Quickly generate an ellipse based on templates and import CAD graphics.

Graphic Transformation: Easily and quickly edit various irregular-shaped images;

Graphic Programming: The pre-input function in the table (gray 0 in the last row of the step) enables rapid input;

Tools: Quickly generate an ellipse based on templates and import CAD graphics.

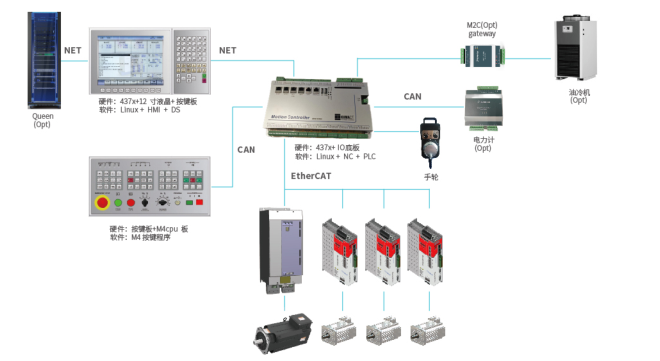

6. CNC System Solution

Cloud Platform

Cloud platforms are industry-specific information management systems designed for the manufacturing sector. They are the foundational solution for enterprises transitioning to Industry 4.0 and the preferable option for smart factories.

Performance and Features

Solving the critical problem of cusp points in servo circular motion during simultaneous motion of dual axes; creation of a friction compensation algorithm for the drive to increase the roundness of the machining center by 20%, which reaches the industry benchmark, Japan's FANUC.

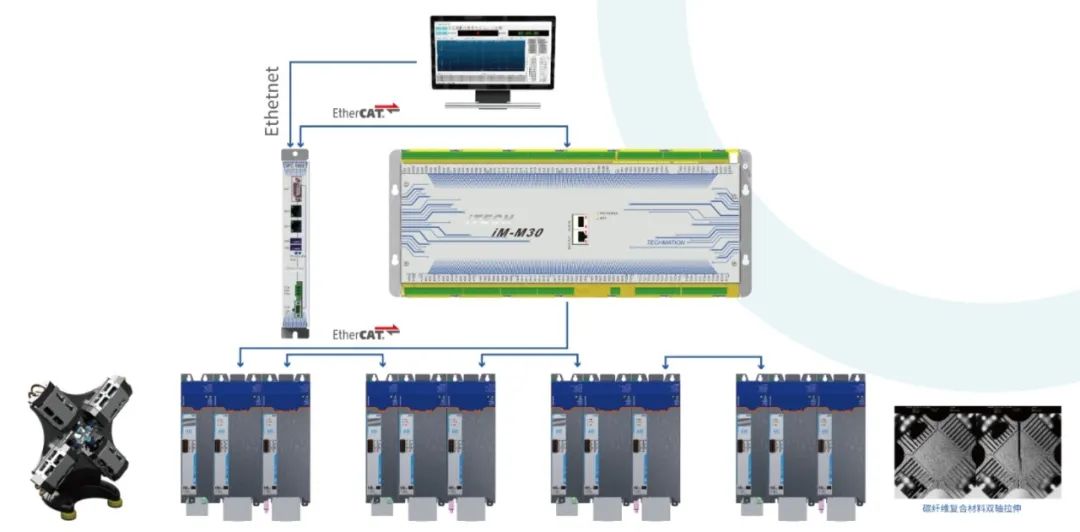

7. Experimental Machine

Planar Biaxial Tensile Test

Four-axis synchronization:To guarantee the precision of test outcomes, it is critical to maintain the deviation of the specimen's center of gravity within ±0.1mm throughout the test.

Loading speed: To obtain high strain loading on the specimen while maintaining synchronization, the four-axis tension and compression speeds should be as high as possible.

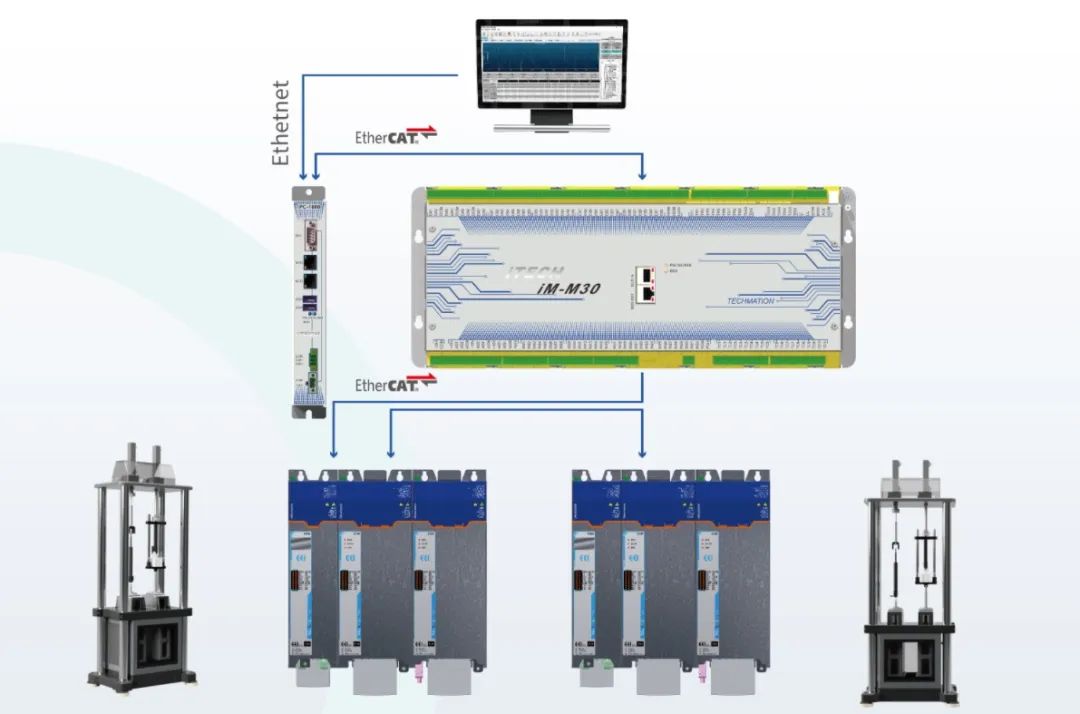

Engine Dynamometer

Shock absorber fatigue test and road condition simulation experiment; allowing for different tests at each individual station; achieving double-high load capacity by dual-station synchronization.

Visit Booth 4-Q36 to discover more superior solutions for industries!

SPECTRUM CONTROL SYSTEMS Established in 2004, Spctrum Control Systems is a wholly-owned subsidiary of Techmation. It is located in the Caohejing Pujiang HI-Tech Park in the Minhang district. It is dedicated to the research and development of control technology for industrial automation, in addition to control technology relevant to power units, precision servo hydraulics, and all-electric control.

Innovation, high quality, sustainability, and efficiency in energy use have always been its guiding principles. It has obtained certifications for clean production, high-tech enterprise, ISO 14001 environmental management system, and ISO 9001 international quality management system. It provides customers with superior-quality services and high-tech, dependable products, and it continues to create value for customers with a genuine and modest manner and a dedication to honesty and perseverance.

Innovation, high quality, sustainability, and efficiency in energy use have always been its guiding principles. It has obtained certifications for clean production, high-tech enterprise, ISO 14001 environmental management system, and ISO 9001 international quality management system. It provides customers with superior-quality services and high-tech, dependable products, and it continues to create value for customers with a genuine and modest manner and a dedication to honesty and perseverance.