HOME

News

Industry trends

【Automated Robotic Arms】Towards Smart Factories: Fully Automated Solutions for Rubber and Plastic Injection Molding Machines

Industry trends

2024-02-27

【Automated Robotic Arms】Towards Smart Factories: Fully Automated Solutions for Rubber and Plastic Injection Molding Machines

Total Solution: Comprehensive Automated Robotic Arm Solution

A comprehensive automated robotic arm solution, commonly known as "one machine with one manipulator in one system," refers to the complete integration of machine tools, robotic arms, and systems into a Total Solution". One machine with one manipulator" represents the process of industrialization, while "one system" indicates the process of informatization. Through a comprehensive integration of the two, we can promote the progress of Industry 4.0.

Based on the most recent data provided by the International Federation of Robotics (IFR), there has been a consistent and substantial annual growth rate of 12% from 2020 to 2023. In light of this situation, Techmation has launched a fully automated robotic arm integration solution specifically designed for the plastic injection molding sector. This solution seamlessly incorporates machine tools, robots, and systems, significantly improving the ease of installation and operation.

Industry 4.0: Intelligent Manufacturing of Smart Factories

Techmation has advanced the industry by introducing an automated robot arm integration solution known as "one machine with one manipulator in one system," while others were still trying to integrate one machine with one robotic arm. In the next 5–10 years, Techmation anticipates that robot arms will be a typical feature in all machine tools, with a "one machine, one manipulator, one system" setup becoming the standard arrangement across the whole industry. This is the vision of a smart factory: "Industrial Automation: Full Intelligence and Smart Manufacturing"!

Currently, more than 25 Chinese machine manufacturers have used this solution, and we have sold it to many nations including India, Turkey, Malaysia, Thailand, Japan, and Russia.

A Comprehensive Solution for Rubber/Plastic Injection Molding Machines

In 2006, Techmation started to focus on developing a control system for fully electric plastic injection molding machines. In 2013, Techmation launched its independently created distributed electric control system called SANDAL, together with servo drives and servo motors, and released its new iDriveCombi common bus servo drives in 2019. Techmation assists customers with their mechanical design and optimization to improve and maintain a competitive advantage in the market for their products.

In order to satisfy customer requests, the SANDAL II system offers ten standard modular injection units, which simplifies design selection for customers. Standardized design efficiently manages the cost of crucial components, minimizes inventory strain for machinery manufacturers, and simplifies later maintenance. Techmation helps machinery manufacturers get ahead in the market for superior all-electric and hybrid machines by providing mechanical design consulting services.

Techmation launched the "one machine with one manipulator in one system" solution in 2019. This solution effectively integrated the operational technologies of injection molding machines and specialized manipulators, leading to significant improvements in machine performance and safety.

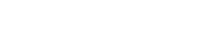

( Industrial Automation & Digital Multi-Solution )

Emphasizing Control Algorithms, Enhancing Informatization Development

The critical element that establishes smart factories as an integral part of Industry 4.0 is their effective implementation of informatization. Exploring the value of data, Techmation has been concentrating on the development of control algorithms, the collection and analysis of data, and remote data maintenance.

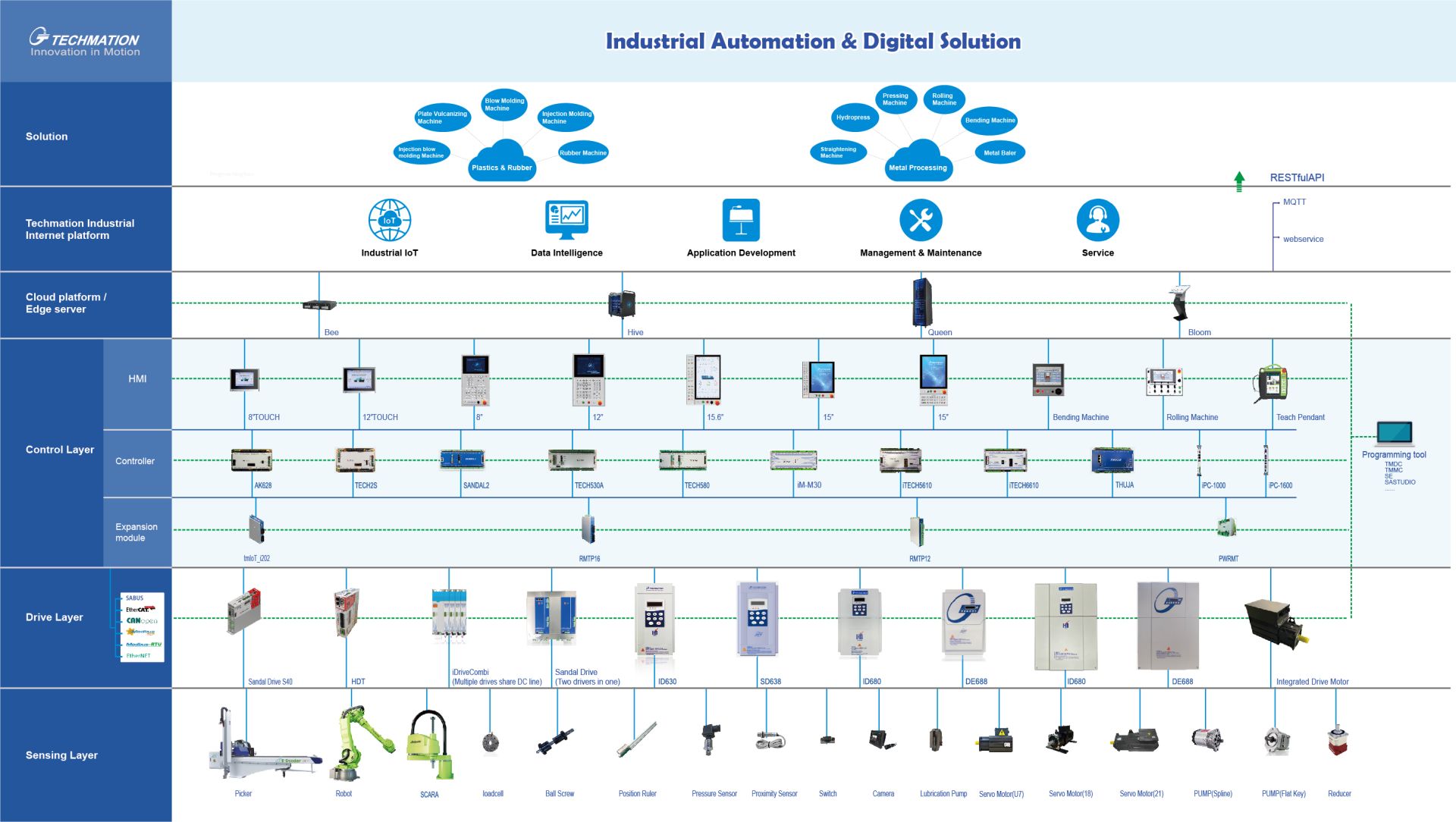

By 2025, Techmation aims to finalize the Industry 4.0 technology platform for plastic processing, which involves utilizing 5G communication technology, artificial intelligence (AI), and efficiently gathering substantial and impactful data (big data) for the purpose of data analysis and implementation. This will help optimize the regular functioning of mechanical equipment, establish an intelligent manufacturing system, modernize production equipment into fully digital machines, and incorporate them into a smart manufacturing ecosystem for plastic processing — IoT cloud platform (Techmation IoT Ecosystem).

(IoT-Cloud-Platform )

David Maa., General Manager of Guangdong Techmation, highlighted that "one machine refers to the control system for fully electric plastic injection molding machinery, one manipulator refers to robotic arms or machine automation, and one system refers to the SANDAL II software system solution. One machine with one manipulator represents industrialization, whereas one system represents informatization. By promoting a profound integration of the two, we can promote the growth of Industry 4.0."