PROGRAM NARRATIVE

Extruder Solution

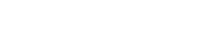

This is a complete control system for the entire production line of plastic extrusion to control and manage all production processes. The hardware of our system includes “itech” series and uses the industrial touchscreen in HMI.

Feature

- Its distributed architecture effectively simplifies the difficulty of wiring and construction, and shortens the time of installation and commissioning.

- The related equipment can be adjusted and controlled synchronously, reducing the difficulty of commissioning.

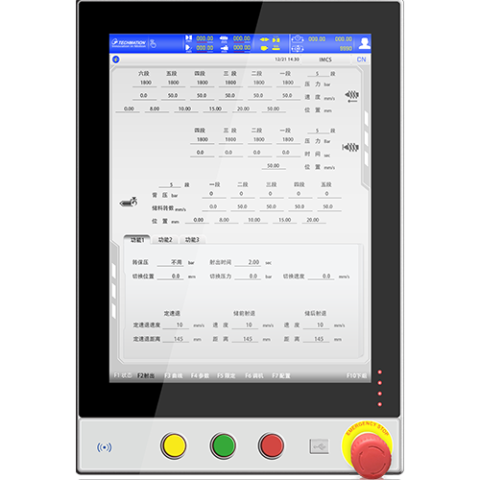

- The driver is with communication functions (optional), which can monitor the process parameters to ensure the stability of the production.

- The PLC structure provides more flexible combination to meet different customer need.

- EtherCat/SA-Bus provides high-speed communication, improves anti-interference performance, and supports long-distance communication.

- The servo motor system (optional) requires smaller installation room (compared with traditional motors), with closed-loop control of the speed. It improves the stability of extrusion, with low speed and high torque.

- It collects and monitors the process parameters (simple version of MES) to ensure the production quality.

- Connectable to the internet (the basis of Industry 4.0) . Process data can be uploaded to the MPS server (optional) for in-depth analysis and management.

- Large HMI reduces buttons and is able to store multiple groups of process parameters for centralized management of information.

- Digital management and information management can effectively control production quality, greatly reduce the requirements for commissioning. It also provides useful data for process analysis which is beyond the reach of traditional control modes.

APPLICATION FIELD

Melt-blown fabric machine/Granulato/Drawing machine/Lamination machine/Film blowing machine

CORRESPONDING PRODUCTS

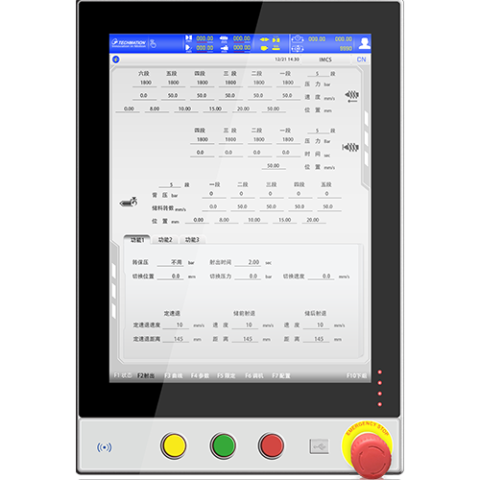

HMI

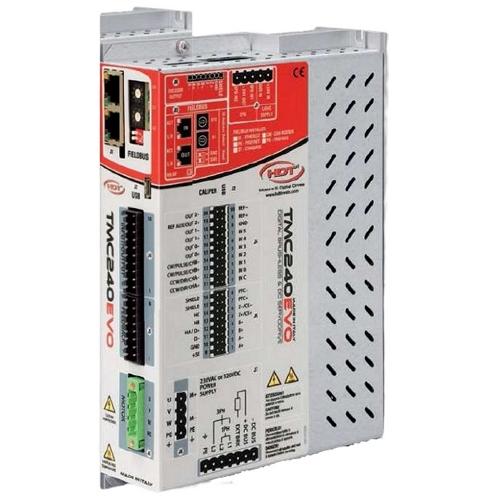

Driver

Servo Motor

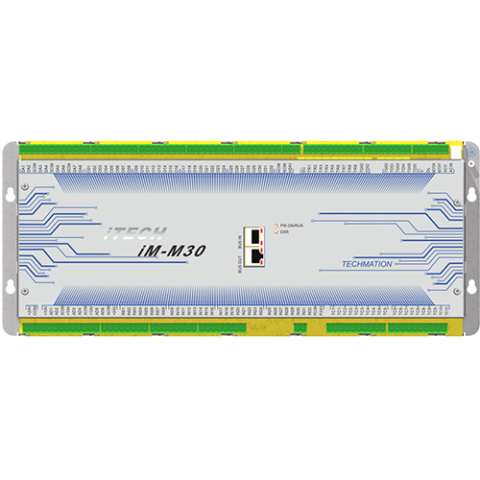

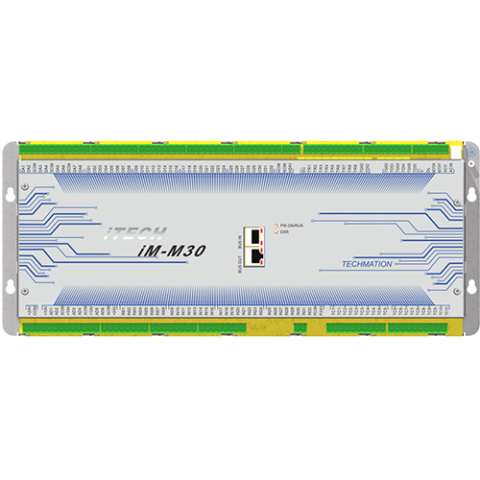

IO Expansion Card

IO Expansion Card

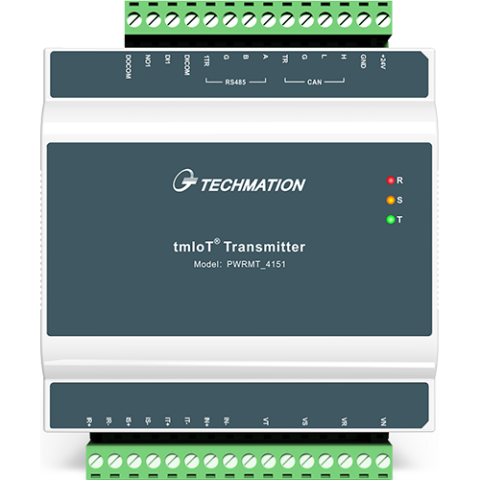

Gateway Module

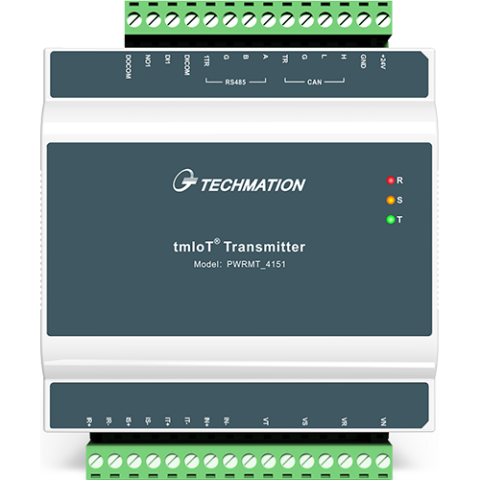

Power Meter

HMI

Driver

Servo Motor

IO Expansion Card

IO Expansion Card

Gateway Module