Horizontal Injection Molding Machine-Hydraulic Solution

We have been deeply engaged in the industry of injection molding machinery for more than 30 years, providing excellent application solutions. We provide cost-effective controllers of different specifications and complete solutions of hydraulic servo energy-saving system for different applications (covering 4kw ~ 160kW) .

Feature

1. Offer a complete portfolio of electric control products named “Tech” series, which are most cost-effective.

2. HYB hydraulic servo energy-saving system solution, constituted by independently developed servo drivers (ID680/ID680N/DE688 series), IPM motors with low inertia and high load capacity (KM series) , highly efficient gear pumps (Eckerle) and low noise screw pumps (Settima) for option, which saves 40% - 70% energy compared with the traditional constant delivery pumps / variable pumps.

3. Customizable design of the HMI display style, startup picture, logo and etc.

4. Customized software support to meet different application need of customers.

5. Rich experience in application of injection molding machinery, integration of standard functions, and complete sets of solutions for standard machines.

6. Digital communication between the controller and the driver, real-time data interaction, real-time upload of actual pressure/actual speed/alarms and other information, routine debugging and parameter modification of the driver through HMI.

Technical Feature

1. Positioning function of mold opening; smooth mold opening and closing through intelligent algorithms not affected by oil temperature or lubrication; positioning accuracy ≤ 5mm; repetition accuracy ≤± 0.5mm. The clamping stability of the manipulator is improved.

2. 1.Rich communication interfaces, supporting EtherNET / CAN_ Bus / SA BUS / RS485 communication, and realize all digital communication among various devices with simplified wiring and reduced interference. Real time transmission of data and information, together with our MES system to easily achieve intelligent factory management.

3. 1.HMI data can be backed up and restored with one click via USB, which is very convenient for debugging in large quantities.

4. Quality curve: display of key molding data, which is more intuitive and convenient for analysis.

5. PPH curve: record of daily production, which is convenient for daily hourly productivity analysis of the month.

Standard injection molding machine / High-speed injection molding machine / Multi-color injection molding machine / Two-plate injection molding machine / Bottle blowing machine / Injection blow molding machine / Rubber machine

Controller

HMI

Servo Driver

Servo Motor

Oil Pump

IO Expansion Card

Temperature Control Card

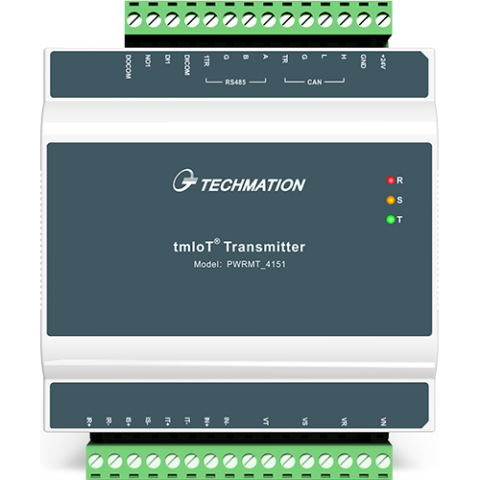

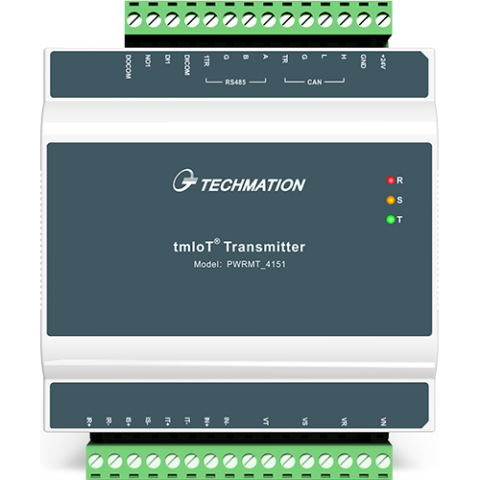

Power Meter

Controller

HMI

Servo Driver

Servo Motor

Oil Pump

IO Expansion Card

Temperature Control Card